Social

SSP Project: 5S & Kaizen for Work Improvement

Elevating Human Potential | Driving Organizations through a Culture of Continuous Improvement

Sermsang Power Corporation Public Company Limited (SSP) reinforces its vision for sustainable development by successfully concluding the "SSP 5S and Kaizen for Work Improvement" workshop. This academic collaboration with the Technological Promotion Association (Thailand-Japan) aims to develop Human Capital and instill a Continuous Improvement Culture as a robust foundation for the organization.

Project Outcomes and Achievements

The "SSP 5S and Kaizen for Work Improvement" project has generated significant positive impacts across various dimensions:

- Project Duration: The project was completed as scheduled over 6 months (July – December 2025), focusing on systematic skill enhancement and performance monitoring.

- Human Capital Impact: A total of 111 personnel successfully completed the training. This cohort includes representatives from executive and operational levels, spanning both central headquarters and field operations nationwide.

- Strategic Coverage: The initiative integrated operations across four core clean energy business units: Wind Farms, Solar Farms, Biomass Power Plants, and Solar Rooftops.

- Knowledge Integration: Learning modules were standardized to international benchmarks, comprising three core curricula: 5S Systems, Kaizen Principles, and Root Cause Analysis (RCA) for sustainable problem-solving.

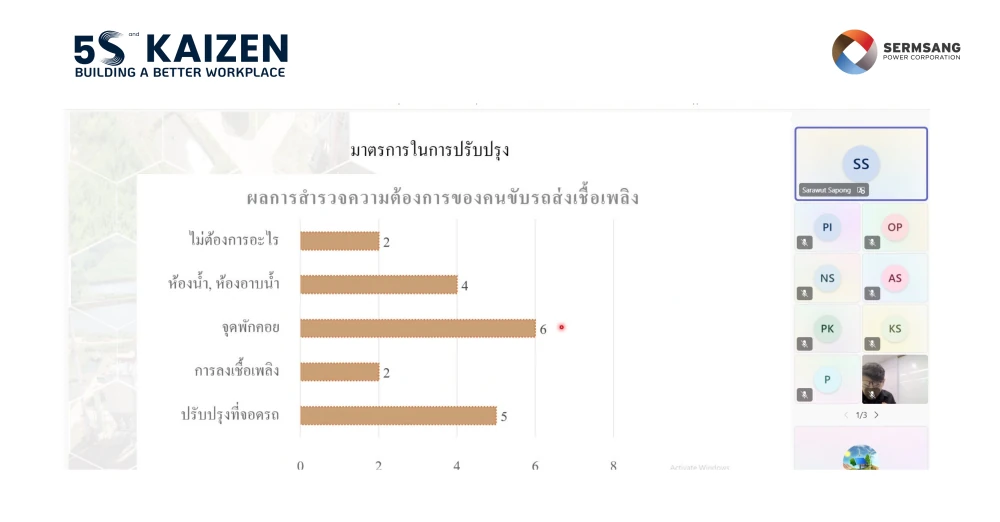

- Tangible Results: The program yielded numerous Kaizen Projects that underwent rigorous analysis and screening. Top projects were presented to a panel of experts to be established as organizational Best Practices.

Strategic Implementation

To achieve the goal of organizational elevation, SSP adopted a Systematic Approach through three primary activities:

- Learning & Workshop: Hands-on workshops focusing on practical tools, such as the Fishbone Diagram for root cause analysis and strategies for Waste Reduction.

- On-site Coaching: Expert consultants, led by Mr. Phurin Khunmongkol, provided in-depth on-site guidance to field teams, translating theoretical knowledge into measurable actions.

- Evaluation & Presentation: Online project presentations were held to facilitate knowledge sharing and receive expert feedback for long-term sustainability.

Best Practice Awards

Concrete evidence of success is reflected in the winning projects, which demonstrated clear quantitative and qualitative results:

- Winner: Kaizen Project Category

- Team: Solar Power Plant, Lopburi Province

- Project: "Optimization of Ventilation Systems within MDB Cabinets"

- Winner: 5S Excellence Category

- Team: Biomass Power Plant, Nakhon Ratchasima Province

- Project: "Workplace Transformation Initiative"

Conclusion

Investing in human resources through this project reflects the "SSP DNA”a commitment to never-ending development. We firmly believe that equipping employees with strong Problem-Solving Skills will lead to reduced processes, enhanced energy management efficiency, and ultimately, increased confidence among all stakeholders.

"SSP commends and thanks all employees for transforming ideas into action and setting a new standard for our organization."