Social

"SSP 5S and Kaizen for Work Improvement" Project

Sermsang Power Corporation PLC. (SSP) has collaborated with the Technology Promotion Association (Thailand-Japan) to implement the "SSP 5S and Kaizen for Work Improvement" training project. This initiative is a core component of the company's commitment to Human Capital Development and fostering a Continuous Improvement Culture. The project is scheduled to run from July to December, with Mr. Purin Khunmongkol serving as the lead instructor.

The primary objective of this project is to enhance the skills of employees at all levels, with a particular focus on those in field operations. The goal is to build a strong foundation for continuous improvement processes and reinforce essential skills required for their roles.

1. Training Workshop

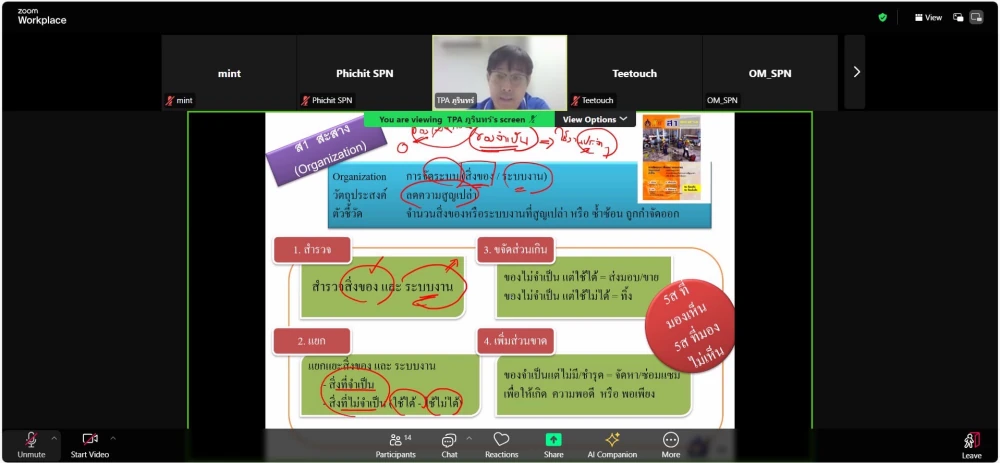

The training methodology employs a blended approach, utilizing both online and onsite formats to accommodate the diverse nature of work and geographical locations. The curriculum is designed to impart critical knowledge and skills through the following modules:

- 5S and Kaizen Principles: This module focuses on understanding Productivity, the SDCA (Standardize, Do, Check, Act) cycle for control, the PDCA (Plan, Do, Check, Act) cycle for improvement, the Kaizen concept, and identifying and eliminating Waste. The training includes hands-on workshops to facilitate practical application.

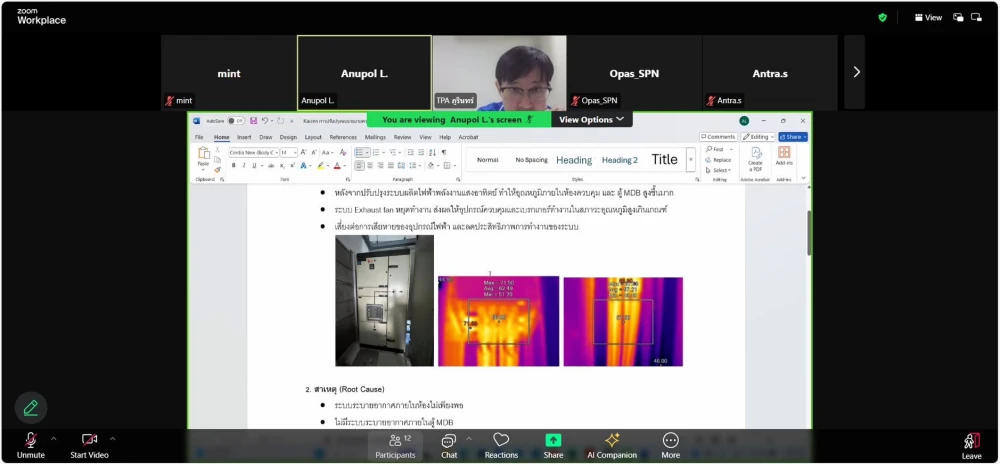

- Root Cause Analysis (RCA): This module trains employees to systematically analyze problems and identify their true causes using tools such as the Cause-and-Effect Diagram (Fishbone) and Why-Why Analysis.

A total of 111 employees are participating, with the breakdown by level as follows:

- Managers and Technicians: 43 employees

- Workers: 63 employees

- RCA Training Group: 25 employees

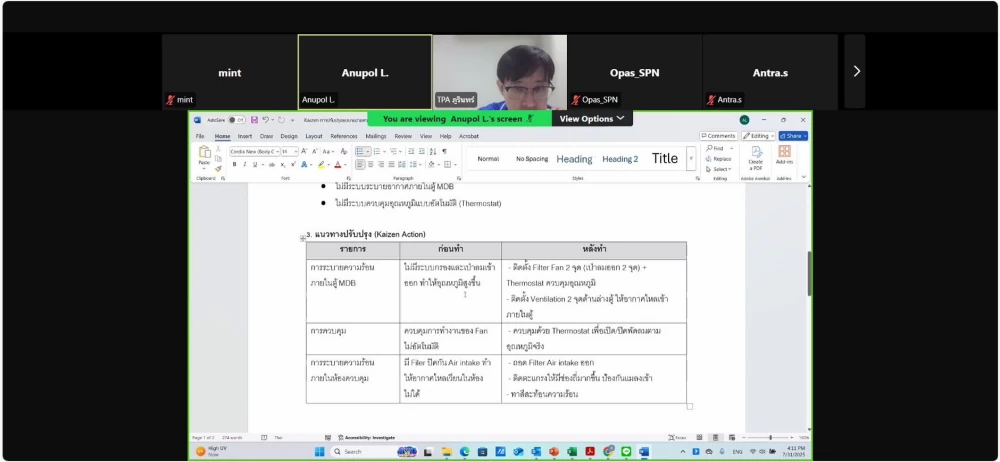

2. In-depth Consulting

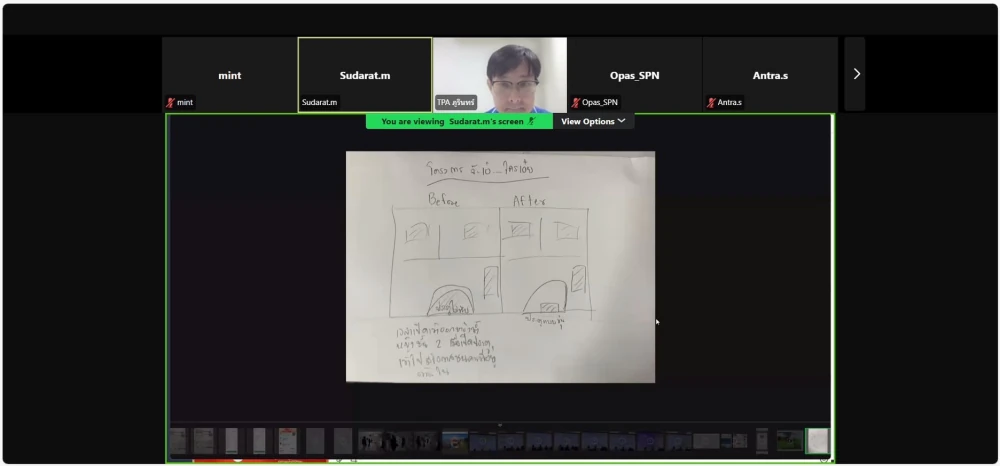

Following the workshops, employees formed groups to develop their Kaizen projects. Instructors provided dedicated guidance through both onsite and online sessions. Onsite consultations were conducted for the Wind Farm, Solar Farm, and Biomass teams, who work in the field, while the Solar Rooftop team received virtual support to ensure all groups could effectively advance their projects.

3. Final Presentation and Consultation

In the final phase of the project, participants presented their developed Kaizen projects and received final feedback from the instructor via an online platform. This stage served as a crucial opportunity for knowledge exchange and project refinement, promoting Continual Improvement throughout the organization.

This project underscores Sermsang Power's vision of prioritizing human capital development. It is expected to empower employees to systematically solve on-site issues, reduce Losses, boost production efficiency, and innovate for enhanced Sustainability and Occupational Health and Safety.